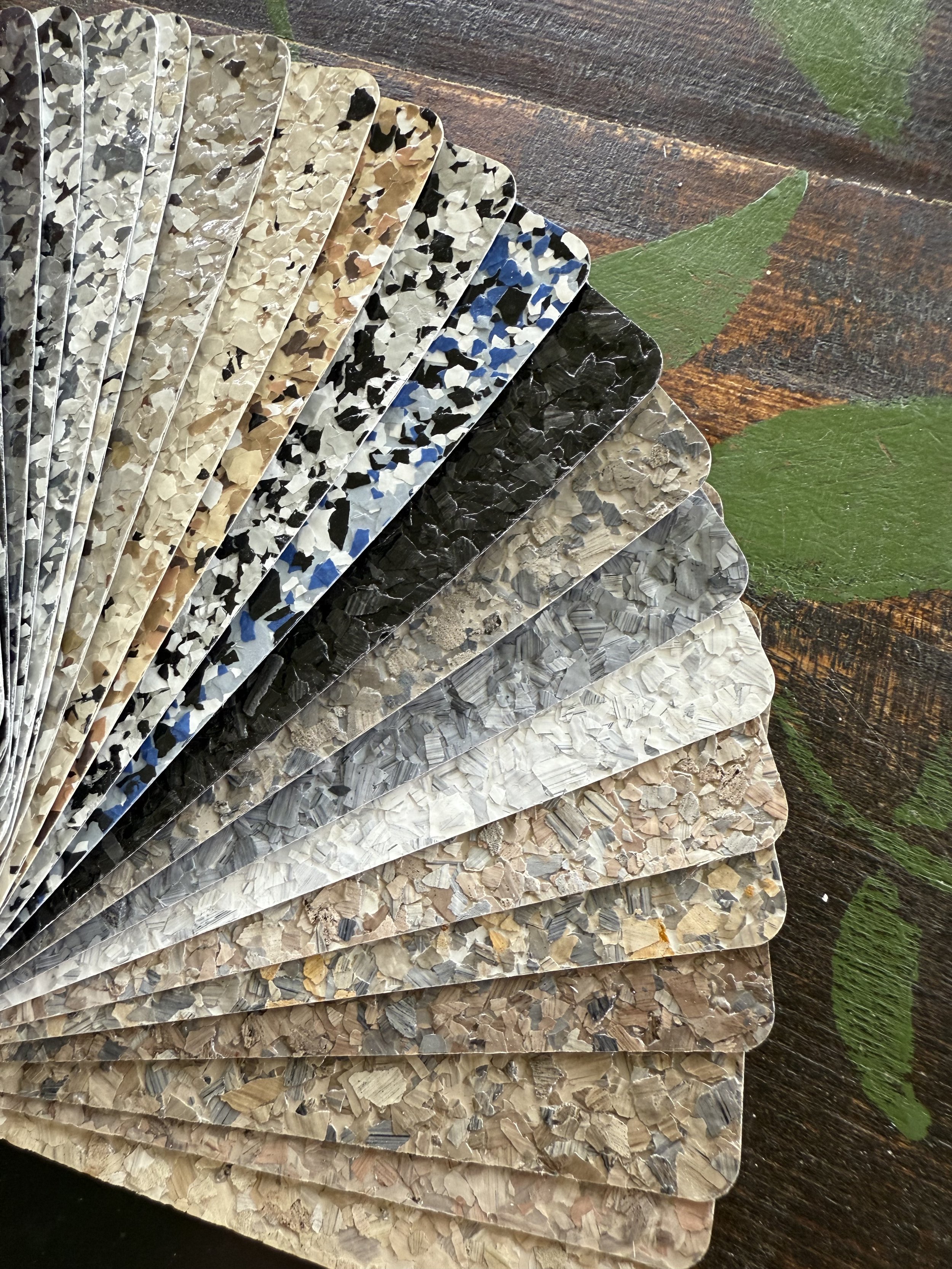

Decorative Flake

Our Flake system is a popular and versatile flooring option that involves “broadcasting”decorative flakes into our durable polyaspartic base coat

Slip resistance, durable, and aesthetically pleasing; This type of system is well-suited for commercial, industrial, and residential settings.

Benefits of a Flake System

Durability:

Both aggregates increase the durability and strength of the coating, resulting in a longer-lasting and more wear-resistant surface, suitable for high-traffic areas.

Slip resistance:

The textured surface created by flake and quartz aggregate improves slip resistance, enhancing safety and reducing the risk of accidents, especially in wet or oily conditions.

Low maintenance:

Floors with flake or quartz aggregate are easy to clean and maintain, as the textured surface hides dirt, stains, and minor imperfections.

Seamless surface:

Flake and quartz aggregate create a seamless surface that is resistant to the growth of bacteria and mold, making them suitable for hygiene-sensitive environments, such as healthcare or food processing facilities.

UV resistance:

These aggregates can improve the UV resistance of the coating, preventing discoloration and degradation over time.

Aesthetics:

Flake and quartz aggregate provide a visually appealing and customizable appearance, available in various colors, sizes, and patterns, giving a unique and decorative finish to the floor.

How the System Works

Surface preparation: This initial step involves cleaning, repairing, and profiling the concrete surface to ensure proper adhesion of the subsequent layers.

Moisture Vapor Barrier (Project Specific): A MVB primer is applied to the prepared concrete surface to improve adhesion, fill pores, and create a strong bond between the concrete and the coating system. Especially with higher presence of moisture.

Base coat: The base coat is the primary layer of the system, consisting of materials such as epoxy, polyurethane, or polyaspartic. This coat provides the main protective and functional properties, including durability, chemical resistance, and wear resistance.

Decorative elements: Include decorative elements, such as flakes/chips to enhance the aesthetics and add texture for slip resistance.

Topcoat: The final layer is a topcoat or sealer, which further enhances the system’s properties, providing UV resistance, additional chemical resistance, and a specific finish, such as gloss or matte.